Table Of Content

It has fully habitable interiors and is fitted with an open-plan kitchen-diner, a bedroom and a bathroom. Cassidy is an updates editor whose main responsibility is to write and edit articles on a range of home improvement topics. Her passion for lifestyle writing began with her editorial apprenticeship at Travel + Leisure magazine. Moving from travel to home, Cassidy now specializes in writing DIY and interior design content. The competition is being held in two phases with submissions for the first phase due on December 8th of 2023. Between the two phases, the company is awarding $1 million and plans to build and showcase the winning designs.

Zero Carbon Homes - The S1600 Prefab Eco Home gets affordably Close

As tenants move into 3D-printed houses in the first years of their commercial listing debut, 3D printing is on a 23 percent compound annual growth rate over the decade to come, according to Grand View Research. These dwellings — often sharing a gray, shapely appearance with a ribbed texture — are even piquing the interest of NASA, which funded a $57 million project to develop tech for moonside 3D-printed infrastructure. There are also companies that will take your building plans and create walls to match that can be delivered and assembled, that can be a great option as it is often cheaper as there is less material waste.

Environmental cost and difficulty of 3D house insulation

This 1022 square foot 3D printed house took 54 hours to build — though this was just the structure. An additional four months for fitting the windows, doors, and other parts was necessary before the home was finished. The team behind this extraordinary achievement now believe they could create a similar house in 33 hours, citing additional knowledge and tech advances. For those of you keeping score, you may be thinking that $475,000 isn’t exactly affordable housing, and you’d be right.

Best 3D Printers in 2024 (All Budgets)

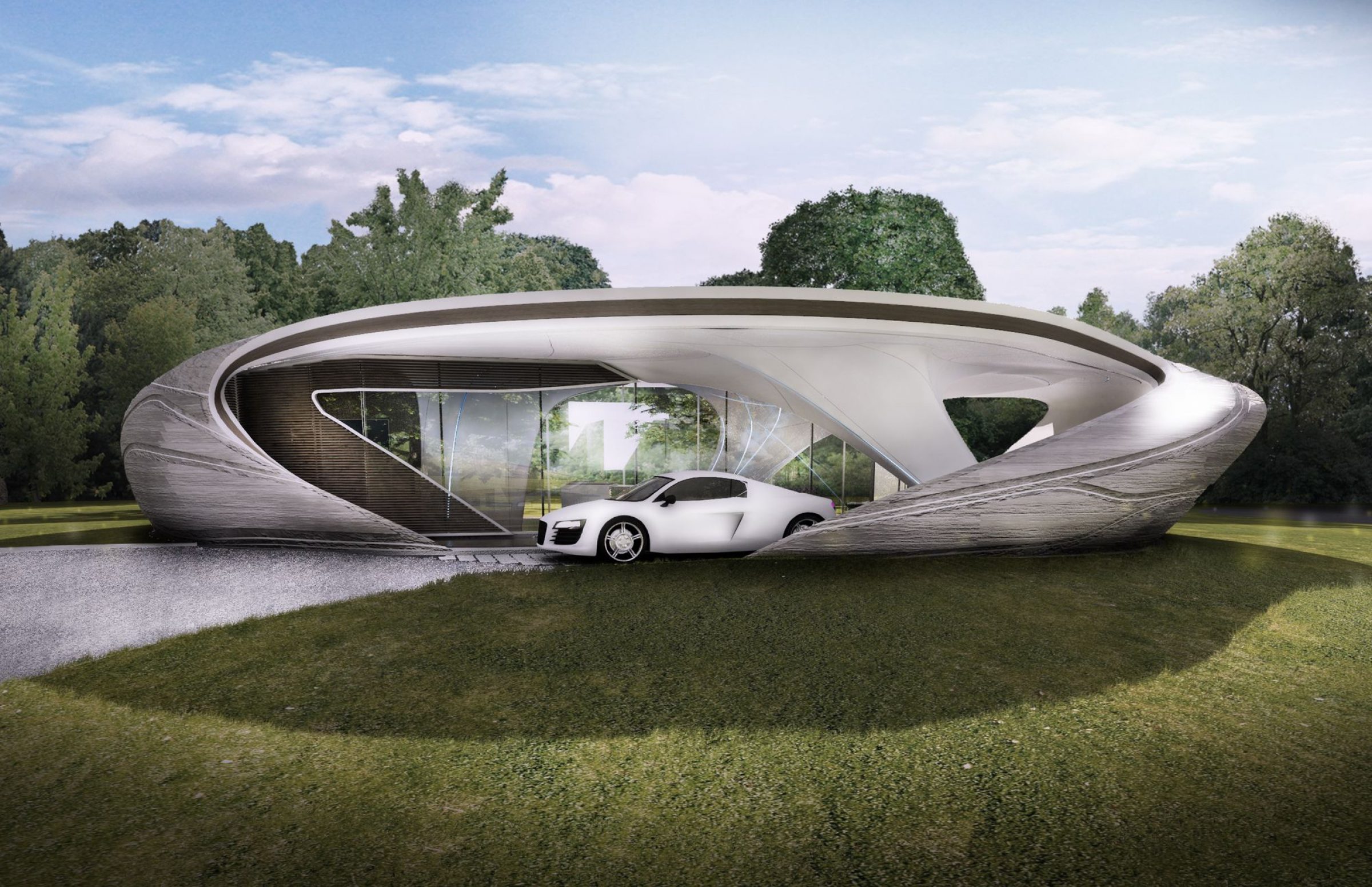

And they’re backing this up with action; this office — claimed to be the most advanced 3D printed building in the world — cost roughly $140,000 to build (not including finishing details) and took 17 days. Perhaps the most exciting part of this build however is the architecture – the house was built to curve around environmentally-protected trees. This is simply not plausible for traditional builds as they are more restricted by the shape of bricks, whereas 3D housebuilding can create curved shapes without issue. This offers potential for more compelling designs, as well as creating custom houses to suit disabled people. We expect much more to come from Apis Cor in Dubai as this building is considered by them to be just a test for larger 3D printed house projects for the future. It is claimed to have been to test whether Apis Cor’s concrete 3D printer could print a building in Dubai’s heat — and passed with flying colors.

This Company Can Print You A New Home—Here’s What You Need To Know

Typically, 3D-printed houses feature free-form, curvilinear shapes made out of a cement mix. Projects span from inhabitable beta prototypes under study to move-in-ready affordable housing and even high-end luxury homes. 3D-printed houses can be made in a matter of hours at a fraction of the cost of conventional construction methods. Our current manufacturing facilities are in Canada, so the best idea of pricing I can give you at the moment is maybe $200 to $300 per square foot CAD, but of course labor and material costs vary by region.

Dutch architecture studio DUS Architects used sustainable bio-plastic to print and construct this eight-square-metre micro cabin in Amsterdam. While ICON is pursuing some “off-world construction” projects, it hasn’t slowed down on its earthly endeavors. In fact, the research from the NASA projects is helping the team develop better, more eco-friendly building materials. To 3D print a house, it may take about 24 hours to three weeks, excluding time for second-fix installations or material transportation if pieces are not printed at the final house location.

The first of these 1,011-square-foot dwellings was printed in 120 hours on-site as 24 separate parts. Matching their backdrop of Eindhoven, a techy city in the Netherlands known for its cutting-edge design, Project Milestone houses resemble elongated boulders with smooth, rounded edges. With extra-thick insulation and a connection to the heat grid, these structures score high marks in energy efficiency, according to online media platform 3D Natives. Its first tenants, Dutch couple Elize Lutz and Harrie Dekkers, received their key on April 30, 2021. NASA has designed, with the company ICON, a 170 m2 3D printed habitat in order to simulate a mission to the Moon (Project Olympus), where buildings could be constructed using resources found on the Moon. For the moment, therefore, unless we use local bio-sourced elements as was done for the Tecla project, the 3D printing of buildings should be limited to these extra-planetary projects...

World's Largest 3D Printer Constructs Homes—A Larger One Was Just Unveiled in Maine - Tech Times

World's Largest 3D Printer Constructs Homes—A Larger One Was Just Unveiled in Maine.

Posted: Wed, 24 Apr 2024 09:10:00 GMT [source]

The company then partnered with a housing non-profit called New Story to build the first permitted 3D-printed home in the United States. With another property under its belt, the company continued to build homes in Nacajuca, Mexico, for local families dealing with extreme poverty. On the design side, Lok sees opportunity to one day offer customized features at a mass scale, without excessive labor costs. For example, she's employed 3D printing to create unique, built-in shelving for various living spaces in the Houston home. 3D-printed houses cost about $10,000 to $400,000 on average, but pricing can vary based on the house’s location, size, amenities and materials used. The 1,407-square-foot house — complete with three bedrooms, two baths and a two-car garage in Riverhead, New York — listed as “the world’s first 3D-printed home for sale” for $299,999 on Zillow.com.

Just as with traditionally constructed homes, 3D-printed homes are available at a variety of price points — though they are generally more affordable. However, construction 3D printing is still in its infancy, and will likely come down in price quickly. The main costs are the materials and labor, and without any labor required except one operator to monitor the print, these costs are dramatically lower. Over in Wallenhausen, Germany, German-based construction company PERI Group started construction on a 3D printed three-story multi-family apartment building, following the success of the two-story home they printed earlier that year. Apis Cor’s build brought 3D printed structures into the public eye, encouraging others to get involved and democratize 3D printed house building.

The demo project, known as BioHome3D, begins with a 600-square-foot prototype that features a fully 3D-printed floor and roof. As a whole, the one-bedroom, one-bathroom building is 100-percent recyclable, made up entirely of biodegradable materials, including wood flour. As a prototype, BioHome3D is equipped with monitoring sensors, measuring thermal, environmental and structural elements, to gather resilience-based data to better inform future designs. With the help of 3D-printing construction manufacturer COBOD, Danish startup 3DCP Group constructed Europe’s first 3D-printed tiny house last year in just five weeks; however, the structure itself printed in just 22 hours. Located in Hostelbro, Denmark, this 398-square-foot structure is composed of three sections that merge at an open, triangular-shaped core.

Nestled away in a gated, hilltop community in southern California, Ehrlich Yanai Rhee Chaney Architects have built a 20-home, net-zero development that aims to consume as much energy as it generates. Constructed in around four months, each home includes two bedrooms and two bathrooms across a 1,171-square-foot space built on top of a hot spring aquifer. Fitted in a modern, minimal aesthetic, these properties include a swimming pool, hot tub, fire pit and floor-to-ceiling windows.

Now the company is working on a new residential project, one that disillusioned homeowners may want to be part of. Our system gives us the scalability needed to execute larger, more complex commercial projects. If you prefer a home with more bells and whistles as your primary residence, you may still want to consider a 3D-printed home as a second home. Dustin Fox, Realtor and owner of Fox Homes, said you should expect to pay $15,000 for a one-bedroom home — and the prices go up from there.

The structural walls are printed from soil, while the cavities are filled with the rice waste, which provides insulation. Rice husks were also used on the interior of the structure, covering the walls and ceiling of the home to form a natural plaster. Built as part of a scheme that aims to become the world's first 3D-printed houses used as rental properties, this boulder-shaped home became the first lived-in 3D-printed home in Europe. The studio combined modern technology and locally sourced clay to produce the homes, using a multilevelled 3D printer that can complete the structure in 200 hours while consuming only six kilowatts of power. In collaboration with 3D-printing specialists WASP, Mario Cucinella Architects looked to vernacular architecture and ancient building techniques to create and develop this low-carbon housing prototype.

Here’s a look at the cost of 3D-printed homes and whether you should consider actually living in one. It’s made from specially formulated concrete with nano polymers that harden faster than normal concrete. Within the first 24 hours, it registers at the standard hardness of a brick house, and after 28 days it’s hardened to that of a bridge. Mighty Buildings and Palari Group plan to develop 15 homes by 2022, each consisting of three bedrooms, two bathrooms, a terrace, and a swimming pool within 1,450 square feet of space. The team starts by adding dry Lavacrete (a special form of concrete), water and additives into a portable mixing machine known as Magma. Once the material is properly mixed and ready to go, Magma pumps it into the Vulcan for printing.

A Dutch couple recently became the first people in Europe to move into a 3D-printed home, so we have rounded up seven examples of 3D-printed houses from around the world. As we mentioned before, it will likely take several years before 3D-printed homes and buildings become mainstream. However, the progress that has been made so far is still exciting, and this new construction method is definitely one to watch. In 2022, the company signed a $60 million contract with NASA and is working to build a construction system that uses lunar materials to build structures to further the goal of an ongoing presence on the moon. Those interested in the program’s progress can sign up on the company’s website for updates. With the Houston home, the team is pushing the industrial printer to its limits to understand how it can streamline the technology, in the quest to quickly build cost-effective and well-designed homes.

But Kamp C ingeniously used the stationary COBOD BOD2 concrete printer to print it on-site in one piece. It’s a low-energy home with a green roof but still manages to blend seamlessly into the surrounding architecture. Sustainable building company Kamp C 3D printed an entire two-story house in Belgium’s Flanders region with Europe’s largest 3D printer. This is in conjunction with their new East 17th Street initiative, a project that hopes to use this innovative technology to build a small community of 3D printed homes in the growing area of East Austin. If you hear of an exciting or innovative building project, there is a high likelihood it will involve Dubai.

No comments:

Post a Comment